Roscamat 400

To consult product specifications, accessories or purchase details:

FEATURES:

Roscamat 400; Capacity M2-M24 (M27)

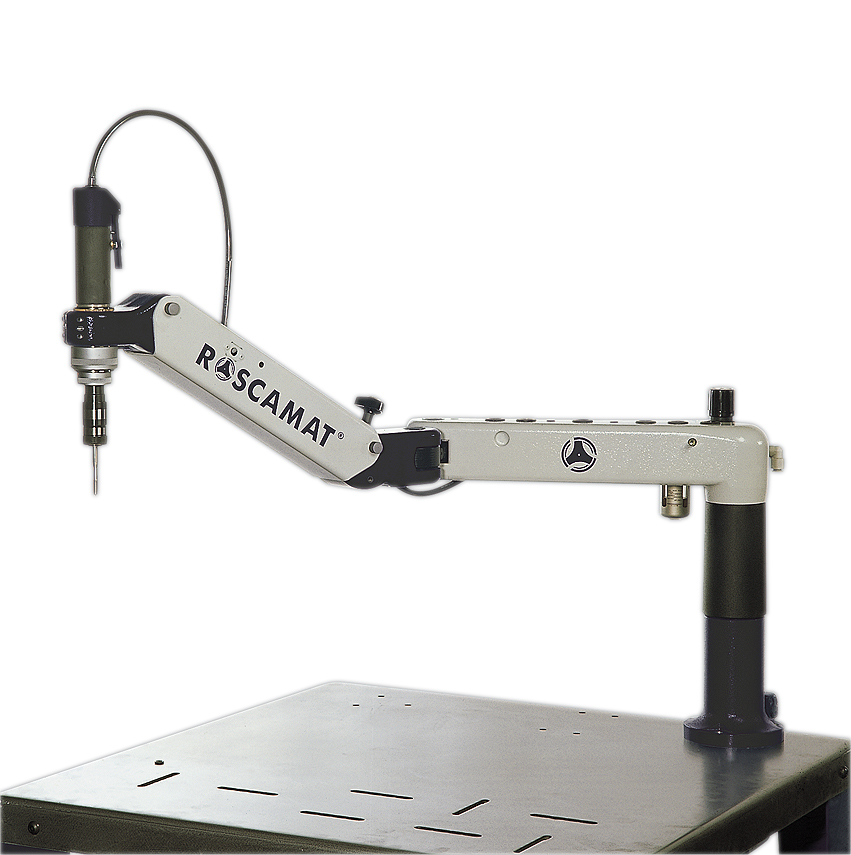

The machine, which can be easily fastened to a work bench or table using three screws or a simple fastening clamp, consists of a radial arm with a 360º turning radius. It is connected to a vertically moving swivel arm that always maintains perpendicularity to the reference plane – which is the machine support surface. It is equipped with a pneumatic motor that includes an air unit (lubricator + filter + regulator) for correct operation. The modular system consisting in a series of 7 quick-change modules (reducers) is provided for coupling to said motor. As a result of this 7 output speeds (90, 170, 300, 550, 750, 1050 and 2100 rpm) are available thus allowing to adapt the tap speed to every type of thread. The handle allows to balance the tilting arm and to position it at the operator’s convenience. The modular system admits the quick-change tap holders with or without safety clutch depending on the intended job (blind or through holes). Thread capacity from M2 up to M24 (M27)

Roscamat 400 VH

The ROSCAMAT 400 can be supplied with an articulated head. This bracket of easy handling can be set in four different positions 90º apart.

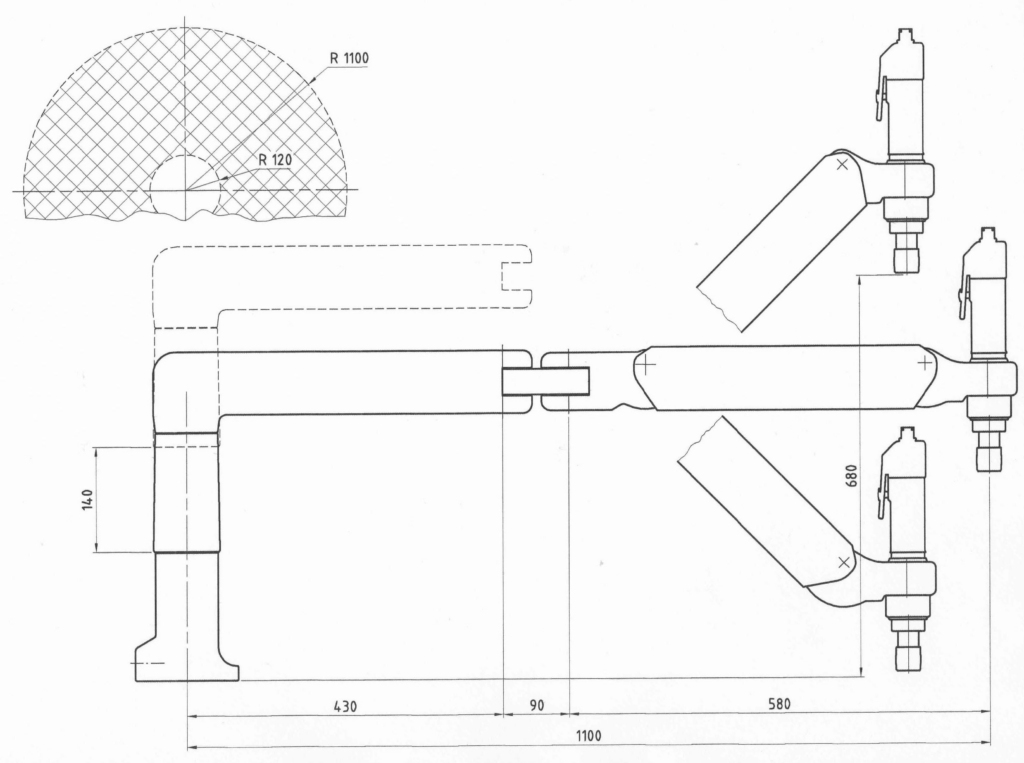

Working Area

Roscamat 400: Radius 1100 mm. Height: 680 + 140 mm.

Roscamat 400 VH: Radius 1220 mm Height: 680 + 140 mm.

Modular system

The modular system provides for a new concept in the use of articulated tapping arm machines. Driven from a single motor, seven different speed modules are available with their relevant power torques. The seven quick-change speed modules provide the speed and torque for each threading type, from M2 to M24 threads.

| Module | Max. Speed ( rpm ) | Max. Torque ( Nm ) | Coupling diameters | Max. Thread aluminio Cast Irons | Max. Threrad Steel <80 kg. | Max. Threrad Steel >80 kg. |

| 90 | 90 | 150 | Ø 31 | M27 | M24 | M22 |

| 170 | 170 | 79 | Ø 31 | M22 | M18 | M16 |

| 300 | 300 | 44 | Ø 19 | M16 | M16 | M14 |

| 550 | 550 | 24 | Ø 19 | M14 | M12 | M10 |

| 750 | 750 | 17 | Ø 19 | M12 | M10 | M8 |

| 1050 | 1050 | 12.5 | Ø 19 | M8 | M8 | M6 |

| 2100 | 2100 | 6 | Con B-16 | To drill up to Ø 8 Aluminium, brass, etc. | ||

Quick-change toolholder

Automatic tap lubrication (OPTIONAL)

The system is comprised of a regulating valve and a lubricant reservoir, and is actuated by the compressed-air system itself. When starting to tap the oil or liquid flow rate can be regulated for the purpose of lubricating the tap during the operation.