Roscamat 500

To consult product specifications, accessories or purchase details:

FEATURES:

Roscamat 500; Capacity M2-M24 (M27)

As regards performance unit R-500 can be considered identical with unit R-400, with the advantageously bigger working area thanks to the longer arms. The machine consists basically of the following elements: radial arm, lockable elbow joint, tilting arm and head. The compressed-air motor is coupled to the latter. Through the foot and by means of three M10 screws the machine can be fixed to a table or workbench. Such attachment can also be obtained by means of a simple clamp. The radial arm and the tilting arm revolve about themselves. The latter tilts therewith always maintaining the perpendicularity to the base reference plane.The machine incorporates an air servicing unit (filter + regulator + lubricator) for the correct operation of the motor. The modular system consisting in a series of 7 quick-change modules (reducers) is provided for coupling to the motor. As a result of this 7 output speeds (90, 170, 300, 550, 750, 1050, 2100 rpm) are available thus allowing to adapt the tap speed to every type of thread. The handle allows to balance the tilting arm and to position it at the operator’s convenience. The modular system admits the quick-change tap holders with or without safety clutch depending on the intended job (blind or through holes). Threading capacity from M2 up to M24 (M27).

Tapping System V, RHM and RHC

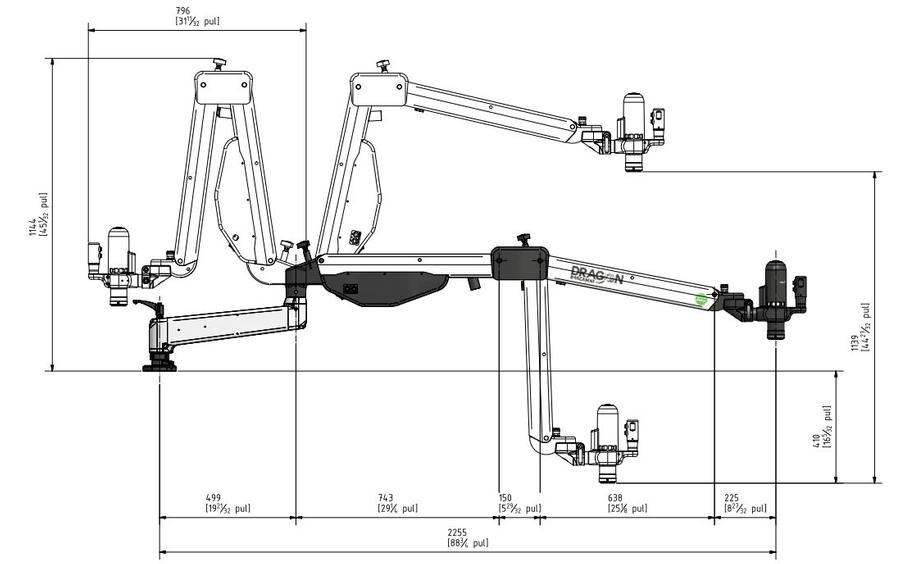

Working Area

Radius: 2.255 mm

Height: 1.139 mm

Quick-change toolholder

Modular system

The modular system provides for a new concept in the use of articulated tapping arm machines. Driven from a single motor, seven different speed modules are available with their relevant power torques. The seven quick-change speed modules provide the speed and torque for each threading type, from M2 to M24(M27) threads.

| Module | Max.Speed(rpm) | Max. Torque(Nm) | Coupling diameters | Max. Thread Aluminum | Max. Threrad Steel<80kg. | Max. Threrad Steel>80kg. |

| 90 | 90 | 150 | Ø 31 | M27 | M24 | M22 |

| 170 | 170 | 79 | Ø 31 | M22 | M18 | M16 |

| 300 | 300 | 44 | Ø 19 | M16 | M16 | M14 |

| 550 | 550 | 24 | Ø 19 | M14 | M12 | M10 |

| 750 | 750 | 17 | Ø 19 | M12 | M10 | M8 |

| 1050 | 1050 | 12.5 | Ø 19 | M8 | M8 | M6 |

| 2100 | 2100 | 6 | Con B-16 | To drill up to Ø 8 Aluminum, brass, etc. | ||

Automatic tap lubrication (OPTIONAL)

The system is comprised of a regulating valve and a lubricant reservoir, and is actuated by the compressed-air system itself. When starting to tap the oil or liquid flow rate can be regulated for the purpose of lubricating the tap during the operation.